Surface finishing

Specialisation delivers

the best results

Surface finishing

Specialisation delivers

the best results

Our treatment shop delivers perfect surfaces for your components!

ELTROPULS offers plasma nitriding, plasma nitrocarburising and oxidation as services at four locations. As a specialist in this process, we protect your components in the best possible way – day after day, piece after piece. From single parts, to prototypes to series-production parts: With 50 modern plasma nitriding plants of various sizes, we guarantee all our customers the best possible treatment without any compromises. Plant capacity can be expanded at short notice. Fully automated series production is also possible.

Components of up to 3.1 m in diameter and up to 3.8 m in length are provided with finishes.

Our tip: Let us convince you with a sample treatment! Our contract heat treatment workshop has mastered nitriding technology like no other.

The benefits of the ELTROPULS treatment shop:

Best results through specialisation

Maximum plant capacity and flexibility

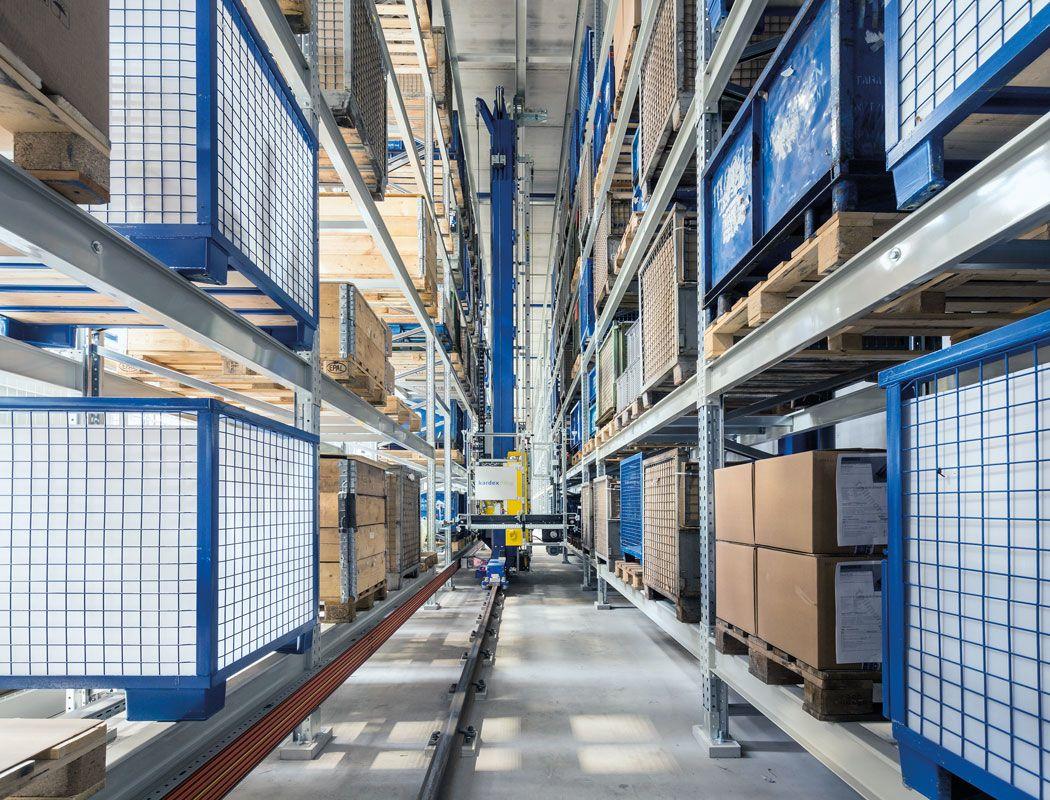

State-of-the-art production systems and sophisticated manufacturing concepts

Premium quality and delivery reliability

Unrivalled development expertise

Maximum production reliability thanks to plant engineering with service on site

Contract surface treatment and plant engineering under one roof

The plus in ELTROPULS: Our sister company ELTROPULS Anlagenbau GmbH works under the same roof. This provides you with maximum production reliability and strengthens your competitive position. After all:

- The plant engineers can immediately resolve any faults during contract surface treatment. Spare parts and service are available around the clock.

We can draw on a large number of treatment systems. No time or quality losses arise as a result. - Series production is our everyday business. Every plant can be adjusted precisely to the surface treatment you require.

- Want to use plasma-nitriding in series production in your own operation but don’t yet have any experience with it? While your nitriding plant is being built next door, we start up your series production on our ELTROPULS plasma plant. Once your new plasma nitriding plant has been delivered, you can avail of fully automated manufacturing at the touch of a button.

Quality

Every one of our employees is committed to the quality of our products and services. We pursue a “zero defect” strategy with total dedication. This is supported by our quality management system. All the processes in production and in our service are governed by continuous improvement in all functional areas and at all levels. You benefit from our certified quality management system according to IATF 16949.

Protecting the environment

Currently, plasma nitriding is the most environmentally friendly nitriding process. Neither the substances used nor those developing during the process are harmful to humans or nature. Our patented nitriding process means minimal pollution, thereby setting new standards. This environmentally conscious, energy efficient and resource-conserving approach is also documented in our certification according to DIN EN ISO 14001, with which we commit ourselves to continuously improving our environmental performance.

Flexible logistics

Time is money – nobody knows better than you that on-time delivery of ordered goods is far more than just convenient. As a global supplier, we ensure your commercial success with flexible and tailored logistics plans and communication structures: Your component will always be in the right place at the right time. You can rely on our supply and deadline reliability – on all five continents.